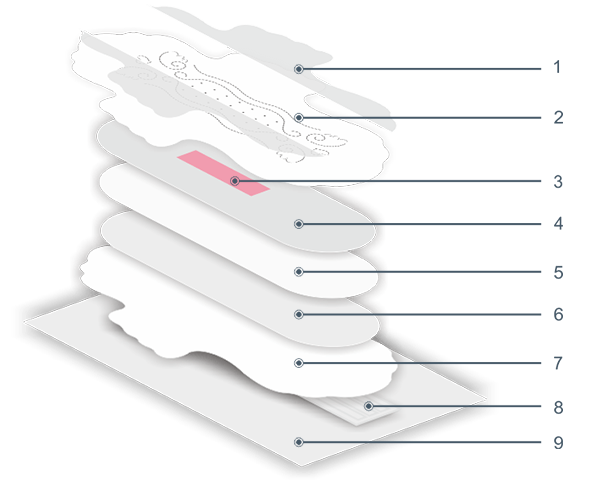

Sanitary napkins, also known as sanitary pads, are absorbent products worn by many women and girls during their menstrual period to soak up the blood flow. Today, most sanitary napkins are made from a combination of natural and synthetic materials. The top layer is generally composed of soft material such as cotton or fluff pulp, while the bottom layer consists of a synthetic material such as polyethylene that prevents leaks. In between these two layers is a super absorbent polymer (SAP) that helps to absorb menstrual fluid.

In this guide , we will take you through the step-by-step process of how sanitary napkins are manufactured. If you are looking to set up your own sanitary napkin manufacturing business, this guide will be a valuable resource. Let’s get started!

The manufacturing process – the different steps involved

The manufacturing process of a sanitary pad can be divided into the following steps:

1.Raw material collection

2.Fluff formation

3.Core building

4.Top sheet making

5.Lamination

6.Wrapping and packing

These processes can be done with the help of a fully automatic or semi-automatic manufacturing plant. For industrial scale production, fully automatic manufacturing plants are used, while for small-scale production and for cottage industry, semi-automatic machines are used. Let’s take a detailed look at each of these manufacturing steps.

The manufacturing process – the different steps involved

The manufacturing process of a sanitary pad can be divided into the following steps:

1.Raw material collection

2.Fluff formation

3.Core building

4.Top sheet making

5.Lamination

6.Wrapping and packing

These processes can be done with the help of a fully automatic or semi-automatic manufacturing plant. For industrial scale production, fully automatic manufacturing plants are used, while for small-scale production and for cottage industry, semi-automatic machines are used. Let’s take a detailed look at each of these manufacturing steps.

Raw material collection

The first step in the manufacturing process is the collection of raw materials. The raw materials used in the production of disposable sanitary napkins include cellulose pulp, rayon, cotton, and a combination of these materials. Moreover, adhesives and dyes are also required. To increase the absorptive capacity of pads, SAP (super absorbent polymer) is also added. This polymer can absorb large amounts of fluid and helps to keep the napkin dry for a longer period of time.

For organic sanitary pads pure cotton, bamboo fiber, banana fiber, and other natural fibers are used. These materials are sourced from suppliers and stored in the factory until they are needed. To make sure that these materials meet quality standards, they are typically tested by the quality control team before being used in production.

Fluff formation

The next step in the production process is fluff forming. The cellulose pulp is inserted into a machine where knives spinning at 3000 rpm shared the pulp into fine fluff. This fluff is mixed with the SAP powder in the desired ratio to increase the absorption capacity of the fluff. Fine fluff is also responsible for the comfort and good feeling on the skin. Besides adding SAP powder to the fluff, some manufacturers also add strips of SAP paper inside the absorbent core to enhance the efficiency of the menstrual pads.

Core building

The third step is the core building of the sanitary pad. The fine fluff mixed with SAP powder from the previous step is fed into a machine known as a core former. This machine shapes the layers of pads. Once the layers of the pad are shaped, the SAP paper strip is sandwiched between these layers in order to make the absorbent core more efficient. Moreover, the SAP paper strip helps to evenly distribute fluid throughout the core and prevents leaks.

After the absorbent core is made, it is fed into another machine. This machine covers the absorbent core with a layer of cotton or rayon fabric. This helps to make the absorbent core more durable and prevents it from tearing easily.

Top sheet making

The next step in production is top sheet making. The top sheet is the layer of fabric that comes into direct contact with the body. It is generally made from a soft material such as cotton or rayon to provide comfort to the user. The top sheet is also perforated to allow fluid to pass through it and be absorbed by the absorbent core.

The sanitary pads can be winged or wingless depending upon the design. The wings are generally made from a soft and comfortable fabric. They have adhesive material which helps to keep the napkin attached in the proper place. They help to keep the pad in place and prevent it from shifting during use.

Lamination

Once the top sheet is made, the outer layer that comes in contact with clothes is laminated with a layer of plastic or polyethylene. This helps to prevent fluid from leaking out of the sanitary napkin and from staining the clothes.

Wrapping and packing

The last step in the manufacturing process is wrapping and packing. In this step, the pads are wrapped in individual wrappers and then packed in boxes or packs. The individual wrapping helps to keep the pads clean and hygienic. The packing of napkins can be of different types i.e. striping pack and wrap easy packing. The wrapped and packed napkins are then sent to the stores where they are sold to the customers.

So these are the steps involved in the manufacturing process of a sanitary napkin. By following these steps, different types of the sanitary napkin can be manufactured such as winged pads, panty liners, thin pad, ultra-thin pad, etc. Now let’s move on to the quality control measures that are taken to ensure the quality of these hygiene products.

What is the importance of quality control in the sanitary napkin manufacturing process?

As you know disposable sanitary napkin was developed to ensure the menstrual hygiene of women and girls. So it is very important to maintain the quality of menstrual napkins as it is directly related to the health of women. There are various quality control measures that are taken to ensure the quality of sanitary napkins. Some of these measures are discussed below:

Raw material testing

To maintain the quality of a sanitary napkin, it is important to use high-quality components. Raw material testing is done by the quality control department at an early stage of the production process. Cellulose, SAP, adhesive, etc. are tested for their quality. These are tested for their purity, strength, and other physical and chemical properties. Only the raw materials that meet the required standards are used in the manufacturing process. This helps to ensure that only high-quality sanitary napkin is manufactured.

Sterilization

Sterilization is another important quality control measure that is taken to ensure the hygiene of sanitary napkin. In this process, all the machines and equipment that are used in the manufacturing process are sterilized. This helps to prevent the growth of bacteria, fungi, and other microorganisms.

It is also important to sterilize the raw materials before using them in the manufacturing process. This is because the raw materials may be contaminated with bacteria, fungi, and other microorganisms. Sterilization helps to prevent the growth of these microorganisms and ensures that only high-quality and hygienic sanitary pads are manufactured. Different types of sterilization processes can be used such as heat sterilization, OE sterilization, etc.

Research and development

Research and development is another important quality control measure that is taken to ensure the quality of sanitary napkin. In this process, new technologies and methods are developed to improve the quality of sanitary napkin.

This helps to develop new and improved products that meet the changing needs of women. Research and development also help to improve the manufacturing process and make it more efficient. This helps to reduce the cost of production and ensures that only high-quality sanitary napkins are manufactured.

These are some of the important quality control measures that are taken to ensure the quality of disposable sanitary napkin. By following these measures, only high-quality and hygienic sanitary napkins are manufactured. This helps to ensure the menstrual hygiene of women and girls.

Conclusion

The Sanitary napkin manufacturing process is a complex process that involves different steps. This can be done by fully automatic or semi-automatic manufacturing units. It is important to follow all the steps properly to ensure the quality of sanitary napkins. Quality control measures are taken to ensure the quality of sanitary napkin. This helps to maintain the hygiene of women and girls.

Besides complexity, the manufacturing process is also resource-intensive and time intensive. Moreover, different NOCs, permissions, and licenses have to be obtained from local as well as federal authorities.

FAQ

The different steps involved in the manufacturing process of the sanitary napkin are as follows:

- Raw material collection

- Fluff formation

- Core building

- Top sheet making

- Lamination

- Wrapping and packing

The different types of sanitary napkins are as follows:

- Disposable sanitary napkins

- Reusable sanitary napkins

- organic/ Biodegradable sanitary napkins

The different raw materials used in the manufacturing of sanitary napkins are as follows:

- Non-woven fabric

- Pulp

- Adhesive

- Super absorbent polymer

- Release paper

- Waterproof backing sheet

The different quality control measures that are taken to ensure the quality of sanitary napkins are as follows:

- Raw material testing

- Sterilization

- Research and development

The different types of sterilization processes that can be used are as follows:

- Heat sterilization

- OE sterilization

- UV sterilization

Gamma irradiation

Research and development help to develop new and improved products that meet the changing needs of women. Research and development also help to improve the manufacturing process and make it more efficient. This helps to reduce the cost of production and ensures that only high-quality sanitary napkins are manufactured.

The different types of packaging materials that can be used are as follows:

- Plastic bags

- Paper bags

- Aluminum foil

- Cardboard boxes